Differences in Mechanical and Physicochemical Properties of Several PTFE Membranes Used in Guided Bone Regeneration

Affiliations

Affiliations

- Department of Bioclinical Sciences, Faculty of Dentistry, Kuwait University, Safat 13110, Kuwait.

- Department of Surgical Sciences, Faculty of Dentistry, Kuwait University, Safat 13110, Kuwait.

- Department of Prosthodontics, College of Dentistry, MBR University, Dubai P.O. Box 505055, United Arab Emirates.

- Department of Chemistry, Faculty of Science, Kuwait University, Safat 13060, Kuwait.

- Faculty of Dentistry, Kuwait University, Safat 13110, Kuwait.

- Department of Preventive and Restorative Dentistry, University of Sharjah, Sharjah P.O. Box 27272, United Arab Emirates.

Abstract

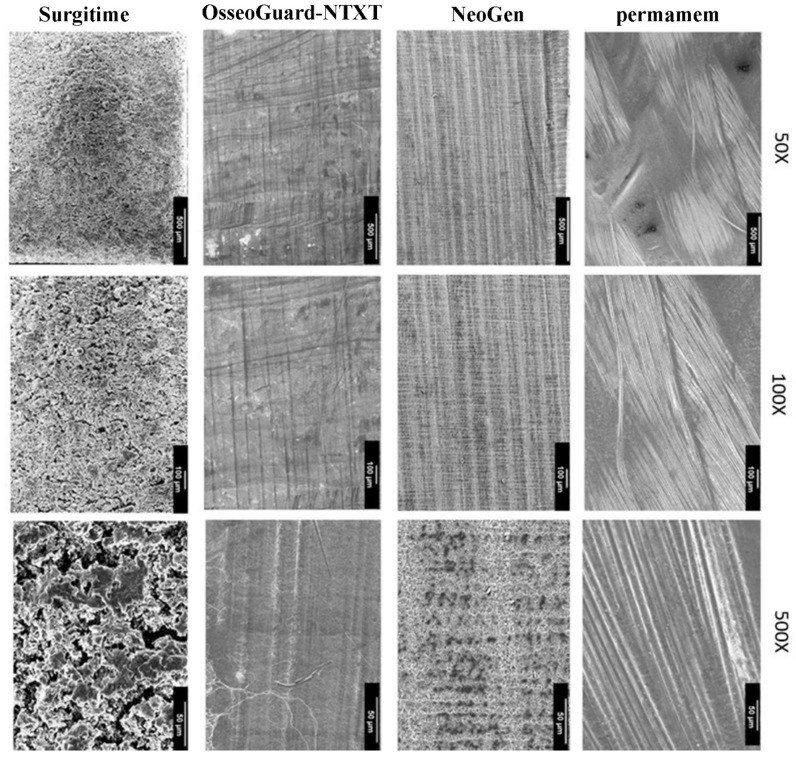

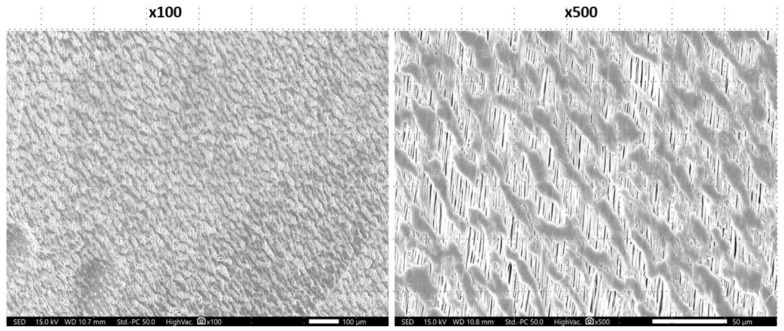

Non-resorbable PTFE membranes are frequently used in dental-guided bone regeneration (GBR). However, there is a lack of detailed comparative studies that define variations among commonly used PTFE membranes in daily dental clinical practice. The aim of this study was to examine differences in physicochemical and mechanical properties of several recent commercial PTFE membranes for dental GBR (CytoplastTM TXT-200, permamem®, NeoGen®, Surgitime, OsseoGuard®-TXT, OsseoGuard®-NTXT). Such differences have been rarely recorded so far, which might be a reason for the varied clinical results. For that reason, we analyzed their surface architecture, chemical composition, tensile strength, Young's modulus, wettability, roughness, density, thickness and porosity. SEM revealed different microarchitectures among the non-textured membranes; the textured ones had hexagonal indentations and XPS indicated an identical spectral portfolio in all membranes. NeoGen® was determined to be the strongest and OsseoGuard®-TXT was the most elastic. Wettability and roughness were highest for Surgitime but lowest for OsseoGuard®-NTXT. Furthermore, permamem® was the thinnest and NeoGen® was identified as the thickest investigated GBR membrane. The defect volumes and defect volume ratio (%) varied significantly, indicating that permamem® had the least imperfect structure, followed by NeoGen® and then Cytoplast TM TXT-200. These differences may potentially affect the clinical outcomes of dental GBR procedures.

Keywords: PTFE membranes; computerized tomography/CT; guided bone regeneration/GBR; micro-CT; nano-CT; physicochemical properties; porosity.

Conflict of interest statement

The authors declare no conflict of interest. Branko Trajkovski is also an employee of botiss biomaterials GmbH.

Figures

Similar articles

Bacterial Growth on Three Non-Resorbable Polytetrafluoroethylene (PTFE) Membranes-An In Vitro Study.

Zelikman H, Slutzkey G, Rosner O, Levartovsky S, Matalon S, Beitlitum I.Materials (Basel). 2022 Aug 18;15(16):5705. doi: 10.3390/ma15165705.PMID: 36013840 Free PMC article.

Jung RE, Fenner N, Hämmerle CH, Zitzmann NU.Clin Oral Implants Res. 2013 Oct;24(10):1065-73. doi: 10.1111/j.1600-0501.2012.02522.x. Epub 2012 Jun 15.PMID: 22697628

Moura JM, Ferreira JF, Marques L, Holgado L, Graeff CF, Kinoshita A.J Mater Sci Mater Med. 2014 Sep;25(9):2111-20. doi: 10.1007/s10856-014-5241-1. Epub 2014 May 22.PMID: 24849612

Carbonell JM, Martín IS, Santos A, Pujol A, Sanz-Moliner JD, Nart J.Int J Oral Maxillofac Surg. 2014 Jan;43(1):75-84. doi: 10.1016/j.ijom.2013.05.017. Epub 2013 Jun 28.PMID: 23810680 Review.

Collagen based barrier membranes for periodontal guided bone regeneration applications.

Sheikh Z, Qureshi J, Alshahrani AM, Nassar H, Ikeda Y, Glogauer M, Ganss B.Odontology. 2017 Jan;105(1):1-12. doi: 10.1007/s10266-016-0267-0. Epub 2016 Sep 9.PMID: 27613193 Review.

KMEL References

References

-

- Rathnayake N., Trajkovski B., Rahman B., Zafiropoulos G.G. Clinical applications and outcomes of non-resorbable polytetrafluoroethylene (PTFE) membranes in guided bone regeneration: Review. J. Int. Dent. Med. Res. 2019;12:1626–1635.

-

- Soldatos N.K., Stylianou P., Koidou P., Angelov N., Yukna R., Romanos G.E. Limitations and options using resorbable versus non-resorbable membranes for successful guided bone regeneration. Quintessence Int. 2017;48:131–147. - PubMed

-

- Bartee B.K., Carr J.A. Evaluation of a high-density polytetrafluoroethylene (n-PTFE) membrane as a barrier material to facilitate guided bone regeneration in the rat mandible. J. Oral. Implantol. 1995;21:88–95. - PubMed

-

- Bartee B.K. Evaluation of a new polytetrafluoroethylene guided tissue regeneration membrane in healing extraction sites. Compend. Contin. Educ. Dent. 1998;19:1256–1258. - PubMed

-

- Chi L., Qian Y., Zhang B., Zhang Z., Jiang Z. Surface engineering and self-cleaning properties of the novel TiO2/PAA/PTFE ultrafiltration membranes. Appl. Petrochem. Res. 2016;6:225–233. doi: 10.1007/s13203-016-0158-x. - DOI

-

- Glaris P., Coulon J.-F., Dorget M., Poncin-Epaillard F. Thermal annealing as a new simple method for PTFE texturing. Polymer. 2013;54:5858–5864. doi: 10.1016/j.polymer.2013.08.011. - DOI

-

- Trobos M., Juhlin A., Shah F.A., Hoffman M., Sahlin H., Dahlin C. In vitro evaluation of barrier function against oral bacteria of dense and expanded polytetrafluoroethylene (PTFE) membranes for guided bone regeneration. Clin. Implant Dent. Relat. Res. 2018;20:738–748. doi: 10.1111/cid.12629. - DOI - PubMed

-

- Begic G., Petkovic Didovic M., Lucic Blagojevic S., Jelovica Badovinac I., Žigon J., Percic M., Cvijanovic Peloza O., Gobin I. Adhesion of oral bacteria to commercial d-PTFE membranes: Polymer microstructure makes a difference. Int. J. Mol. Sci. 2022;23:2983. doi: 10.3390/ijms23062983. - DOI - PMC - PubMed

-

- Jiang Y., Bo Li B., Tanabashi Y. Estimating the relation between surface roughness and mechanical properties of rock joints. Int. J. Rock Mech. Min. 2006;43:837–846. doi: 10.1016/j.ijrmms.2005.11.013. - DOI

-

- Park H., Tinh V.D.C., Kim D. Surface hydrophilization toward the proton conductive porous PTFE substrate impregnating SPEEK for polymer electrolyte membranes. Progr. Org. Coat. 2022;163:106643. doi: 10.1016/j.porgcoat.2021.106643. - DOI

-

- Wang K., Hou D., Wang J., Wang Z., Tian B., Liang P. Hydrophilic surface coating on hydrophobic PTFE membrane for robust anti-oil-fouling membrane distillation. Appl. Surf. Sci. 2018;450:57–65. doi: 10.1016/j.apsusc.2018.04.180. - DOI

-

- Wenzel R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936;28:988–994. doi: 10.1021/ie50320a024. - DOI

-

- Wang X.L., Qu Z.G., Lai T., Ren G.F., Wang W.K. Enhancing water transport performance of gas diffusion layers through coupling manipulation of pore structure and hydrophobicity. J. Power Sources. 2022;525:231121. doi: 10.1016/j.jpowsour.2022.231121. - DOI

-

- Stamopoulos A.G., Tserpes K.I., Prucha P., Vavrik D. Evaluation of porosity effects on the mechanical properties of carbon fiber-reinforced plastic unidirectional laminates by X-ray computed tomography and mechanical testing. J. Compos. Mater. 2016;50:2087–2098. doi: 10.1177/0021998315602049. - DOI

-

- McGaughey A.L., Karandikar P., Gupta M., Childress A.E. Hydrophobicity versus pore size: Polymer coatings to improve membrane wetting resistance for membrane distillation. ACS Appl. Polym. Mater. 2020;23:1256–1267. doi: 10.1021/acsapm.9b01133. - DOI